Aluminium composite panels

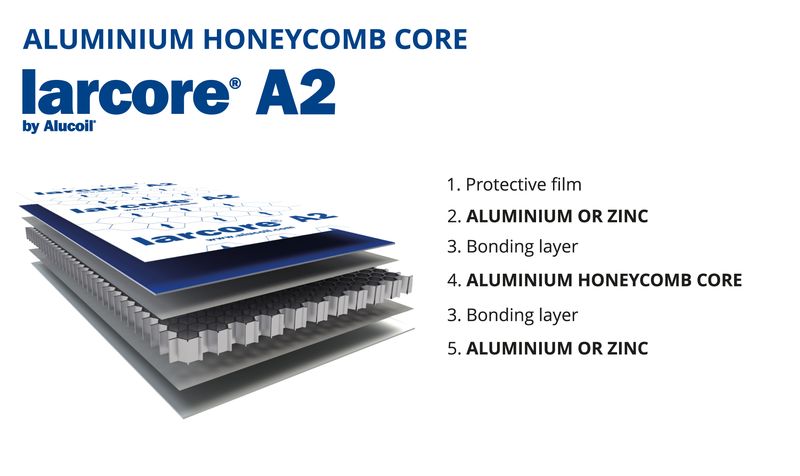

Aluminium composite panels (ACP) are cladding panels with a thin layer of aluminium fixed on both sides. The boards are stiffened on the inside by a thermoplastic polyethylene resin or a refractory layer.

Decorative tiles can be used both outdoors and indoors.

Warranty on coating up to 40 years

Easy to clean

Resistant to UV radiation, moisture and chemicals

We represent the brandE:

Decorative tiles, for outdoor and indoor use.

Aluminium composite tiles are finishing tiles with a thin layer of aluminium fixed on both sides.

Between the layers there is a mineral fire retardant layer of either class B-s1,d0 or A2 (according to EN 13501-1).

Our range of composite tiles includes:

The outer layer is usually coated with a highly durable PVDF paint, anodising or some other interesting finish.

It is also possible to produce so-called chameleon surfaces , i.e. tiles coated with a multi-layered chameleon paint that changes colour when viewed from different angles.

Advantages of aluminium composite board

Alumiinium komposiidist fassaad

Alucoil komposiitplaadi omadused

Aluminium composite board is an excellent decorative material for indoor and outdoor use.

Weight

Light weight, which reduces the time needed to process composite panels, as well as facilitating and speeding up the assembly of panels on objects.

With 30-50% less weight than conventional metal panels, composite panels reduce the load on the load-bearing elements of architectural structures.

Weatherproofing

Warranty on the coating up to 40 years. Resistant to UV rays, moisture and various chemicals, salts, etc.

Fire safety

Panels available in both Bs1,d0 and A2 reaction to fire classes.

Composite panels filled with a special fire-resistant material are offered for use in areas with increased fire risk.

Shape retention and maintenance

Composite board has a high dimensional stability – the boards do not warp, are perfectly straight and smooth.

Bending does not crack the outer covering of the sheets. The panels will not deform to any lesser extent in windy or sunny conditions.

After a few years of use, the panels can be easily cleaned with neutral detergents and water.

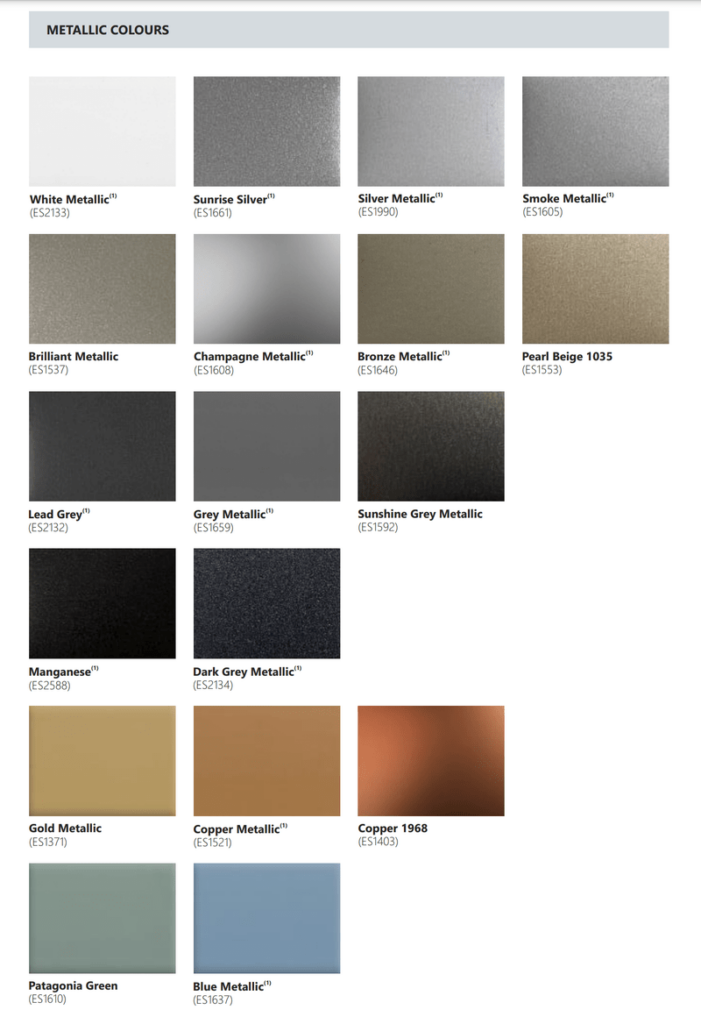

Alucoil colour range

Aluminium composite panels can be produced in a wide range of different colours, and it is also possible to produce ‘chameleon’ surfaces, i.e. panels coated with a multi-layered chameleon paint that changes colour when viewed from different angles.

In addition, we also offer copper, brass, patinated copper, stainless steel and zinc-coated composite plates.

Choose the right colour and collect ideas for your façade division

ALUCOIL, a manufacturer of aluminium composite tiles, has created an online environment where you can browse Alucoil projects, materials and colours from around the world.

We’ve published an explanatory guide to the online environment in Estonian in an earlier post.

Referents

Rotermanni R18

As a contemporary architectural landmark, the Rotermann Quarter is distinguished by its exclusive new buildings, to which we have also contributed. ALUCOIL aluminium composite panels have been used as façade materials for the red and gold houses. The colour scheme of the façade (see also the post: “What colour façade to choose?“) is distinctive, and stands out to passers-by with both night-time lighting and daytime sun.

The shade used is “Alucoil Sparkling Antracite Grey“.

The gold and red houses were completed in 2017 by the main contractor Nordecon AS.

Frequently asked questions

Request a quote

We can help you design the right fastening sequences, ways and, if necessary, train your installation teams.